News

Denison Announces Completion of Highly Successful Phoenix ISR Field Test Program

TORONTO, Oct. 28, 2021 /CNW/ - Denison Mines Corp. ("Denison" or the "Company") (TSX: DML) (NYSE American: DNN) is pleased to announce the initial results of a highly successful In-Situ Recovery ("ISR") field test program ("2021 ISR Field Test") completed within the commercial-scale ISR test pattern installed in the Phase 1 area of the high-grade Phoenix uranium deposit ("Phoenix") at the Company's 95% owned Wheeler River Uranium Project ("Wheeler River" or the "Project") in northern Saskatchewan. View PDF Version

- Achieved the commercial-scale production flowrate assumed in the Pre-Feasibility Study ("PFS") prepared for the Project in 2018.

- Demonstrated hydraulic control of injected solution during ion tracer test – reporting no elevated values of the tracer element in the monitoring wells surrounding the commercial-scale test pattern.

- Established breakthrough times between injection and recovery wells, spaced 5 to 10 meters apart, that are consistent with previous 'Proof of Concept' hydrogeological modelling conducted by Petrotek Corporation ("Petrotek").

- Completed 'clean-up phase' following tracer test demonstrating ability to remediate the test pattern – reducing tracer concentrations to as low as 4% of peak test levels within eight days of remediation.

David Cates, Denison's President & CEO, commented, "We are pleased to have safely and successfully completed another significant ISR field program at Phoenix. Our evaluation team and field staff have worked diligently over an eight-month period to expertly carry out a complex project execution plan that has delivered the data and results necessary for our Company to continue our industry-leading efforts to further de-risk the application of the ISR mining method in the Athabasca Basin region.

While our previous test work has provided considerable support for the use of ISR at Phoenix, the achievement of the targeted flowrate from the PFS in a commercial-scale well pattern located within Phase 1 of Phoenix, and the tangible demonstration of our ability to control fluid flows during the tracer test, together mark another highly significant de-risking milestone for the Project.

With the field test completed and the Company well capitalized, our technical team is moving full-steam ahead with the development of our field plans for 2022 while also supporting the recent launch of the formal feasibility study process."

The 2021 ISR Field Test program was designed to further increase confidence and reduce risk in the application of the ISR mining method at Phoenix – with the detailed results providing the necessary datasets for the permitting and preparation of a planned lixiviant test in 2022, which is expected to support the completion of the recently announced Feasibility Study (or "FS") for the Project (see press release dated September 22, 2021).

This press release constitutes a "designated news release" for the purposes of the Company's prospectus supplement dated September 28, 2021, to its short form base shelf prospectus dated September 16, 2021.

Test Pattern Installation

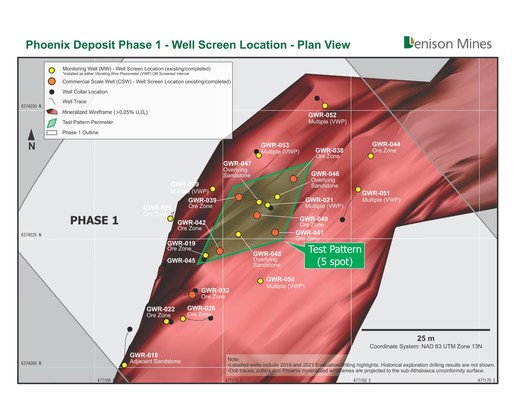

A test pattern consisting of five commercial-scale wells ("CSWs"), including GWR-038 to GWR-042, and 10 additional small diameter monitoring wells ("MWs") (together described as the "Test Pattern"), was successfully installed within the Phase 1 area of the Phoenix deposit (see Figure 1) during the summer months (see press release dated July 29, 2021).

Three methods of permeability enhancement were successfully evaluated on the five CSWs, with post permeability enhancement testing resulting in observed improvement in hydraulic responses and inter-well connectivity within the Test Pattern. These results exhibit and confirm the ability to engineer additional access to the natural permeability within the deposit. Permeability enhancement methods included the use of the MaxPERF drilling tool as well as wireline-conveyed tools designed to perforate and stimulate well production using a controlled propellant. The wireline tools can effectively "clean out" restricted pathways within the well screen, well bore, and the geological formation and provide increased flow rates in the wells by intersecting and connecting to the naturally occurring fractures within the ore zone.

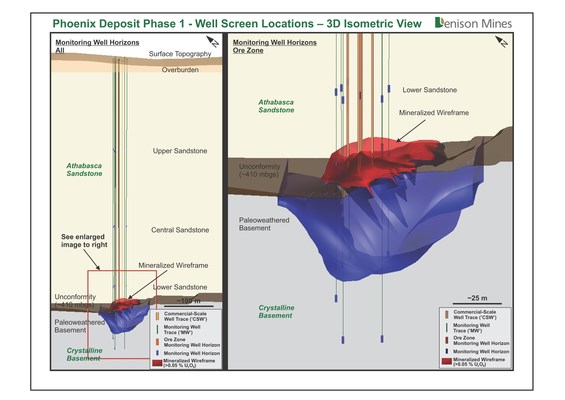

Twenty single-well injection tests were completed on the Test Pattern to evaluate natural permeability and the efficiency of permeability enhancement methods deployed in the CSWs. Nine single-well pump tests were completed amongst the five CSWs and four of the MWs to evaluate permeability, sustainable pumping rates, hydraulic connectivity, and baseline groundwater conditions. Importantly, testing showed good hydraulic connection between the CSWs in the ore zone horizon and no significant responses in any of the MWs in overlying or underlying horizons (see Figure 2). One step-rate injection test was conducted on the center CSW (GWR-040) to evaluate hydraulic connectivity, maximum injection rates and injection pressures.

Full-Scale Well Pattern Pump and Injection Test

A full-scale well pattern injection and pumping test was conducted to determine hydraulic connectivity for the Test Pattern as a whole, and to evaluate potential production rates for the pattern. The test was run as a modified 4-spot pattern as there was an unanticipated failure of the submersible pump in GWR-042. During the test, injection rates were matched to pumping extraction rates for balanced flow in the Test Pattern. Pumped groundwater from each of the outer wells (GWR-038, GWR-039, and GWR-041) was recycled for injection in the center well (GWR-040) to create a closed system. Production rates for the Test Pattern achieved a sustainable rate of 45.3 litres per minute ("L/min") injection in GWR-040 with minimal pressure on surface balanced with 15.1 L/min extraction at each GWR-038, GWR-039 and GWR-041. This test fundamentally achieved the 50 L/min flow rate assumed in the PFS for an operating well pattern. Hydraulic control of the Test Pattern was confirmed by no significant hydrologic responses observed in any of the overlying or underlying monitoring wells.

Ion Tracer Test

Following the full-scale injection and pumping test, an ion tracer test was completed using the 4 functional CSWs in the Test Pattern. Flow rates were run at the same levels as the full-scale well pattern test with 45.3 L/min injection at the center well and a balanced extraction flow of 15.1 L/min at each of the three outer wells. The ion tracer, consisting of a 15% concentration of potassium chloride (KCl) by weight, was injected as an initial slug into the Test Pattern at GWR-040, followed by a chase phase involving the recirculation of water extracted from the three outer wells (closed system). The chase phase continued until peak concentrations of the ion tracer, measured in total dissolved solids ("TDS"), were observed at the three extraction wells (GWR-038, GWR-039 and GWR-041), followed by a decline in TDS prior to commencement of a remediation test.

Breakthrough of the ion tracer, as observed by an increase in the TDS, occurred at the three extraction wells within 9 hours (GWR-039), 12 hours (GWR-041), and 14 hours (GWR-038). These breakthrough times observed during the field test are consistent with previous hydrogeological modelling conducted by Petrotek (see press release dated June 4, 2020).

Remediation Test

After completion of the ion tracer test, a "clean-up" remediation test was conducted to simulate the ability to remove injected fluid from the Test Pattern. For this test, injection was halted at the center well (GWR-040) and the three extraction wells were pumped to remove the remaining injected ion tracer. Tracer concentrations measured during the eight-day clean-up simulation, as observed by field TDS measurements, declined to as low as 13% of the peak TDS value in GWR-038, 11% of the peak TDS value in GWR-041, and 4% of the peak TDS value in GWR-039.

Hydrogeological Monitoring

Monitoring during the ion tracer test and subsequent clean-up test included: 376 field measurements of TDS from the CSW extraction wells to identify tracer concentrations; logging of water levels in each of the CSWs along with all of the surrounding MWs at five-minute intervals; logging of TDS values at five-minute intervals in the three overlying MWs to confirm the absence of any tracer concentrations in the overlying horizons; and daily groundwater sampling to send for lab analysis to confirm TDS values measured in the field and the exact concentration of the KCl tracer.

The ability to maintain hydraulic control was established by sampling the three overlying MWs for TDS values before and after the ion tracer test. No elevated values in TDS were observed during the test, thus confirming there was no migration of the tracer to overlying horizons.

Data collected as part of the 2021 field program will be utilized to update the Phoenix hydrogeological model, and will provide the necessary data for the permitting and preparation of a lixiviant test planned for the Test Pattern in 2022.

Ongoing Permeameter Analysis

In addition to the hydrogeological tests described above, over 1,000 drill core samples were collected from historic holes, re-logged for hydrogeologic characteristics, and analyzed for permeability utilizing the permeameter on-site. Samples were selected to ensure the database of on-core permeability results included representative samples from all of the planned mining phases at Phoenix.

COVID-19

The Company is committed to ensuring that the Wheeler River site is a safe operating environment for its staff and contractors and that the Company's field activities do not compromise the health and safety of the residents of northern Saskatchewan. In 2020, the Company's Occupational Health and Safety Committee in Saskatoon developed a comprehensive guide for the safe resumption of work at Wheeler River. The protocols consider the unique health and safety risks associated with operating a remote work camp amidst the ongoing COVID-19 pandemic. Public health guidelines and best practices (including testing) have been incorporated into the Company's protocols.

The 2021 ISR Field Test was completed over an eight-month period and involved the on-site support of over 100 different staff and contractors. COVID-19 rapid testing was completed regularly at the site, with no positive cases reported during the entire program. These results demonstrate the effectiveness of the Company's COVID-19 protocols and helped to ensure that the extensive scope of the 2021 ISR Field Test was completed on schedule.

Groundwater Measurement and Sampling Procedures

Individual wells are monitored and logged at five-minute intervals utilizing In-Situ LevelTROLL 700 Data Logger transducers installed on cables below the water table, providing water level, water pressure, and temperature data based on factory calibrations. Manual water level readings are recorded using a Heron Instruments Inc. water level tape upon commencement and completion of each log. Flow rates and cumulative flow volumes are measured 'in-line' on injection and extraction hose lines and recorded at four-hour minimum intervals, using Great Plains Industries Inc. FLOMEC Turbine Stainless Steel Flowmeters calibrated to factory specifications. TDS measurements from individual wells are monitored and logged at five-minute intervals utilizing In-Situ AquaTROLL 200 Data Logger transducers installed on cables below the water table and in flow cells on surface 'in-line' with the extraction hose lines. The AquaTROLLs provide water level, water pressure, temperature, and conductivity data based on factory calibration. TDS is calculated from conductivity measurements via the AquaTROLLs based on factory calibration formulas as well as field calibrations using standard solutions of known conductivity. The data from LevelTROLL and AquaTROLL transducers are downloaded using Win-Situ 5 software. Manual field measurements of TDS, conductivity, pH, and dissolved oxygen are taken from samples collected from extraction wellhead sample ports, at 4 hour intervals during active testing, using an YSI ProDSS Handheld Multiparameter Water Quality Meter. The Water Quality Meter is field calibrated at a minimum of once per week, based on manufacturer specifications, using solutions of known pH and conductivity. Groundwater samples for lab analysis are collected from wells following the Company's standard Groundwater Sampling Procedure for Wheeler River and are sent to Saskatchewan Research Council ("SRC") Environmental Analytical Laboratories located in Saskatoon. Samples are collected from the sample port of the wellhead for extraction wells, during pumping of MWs and after wells are purged. Quality control groundwater samples for lab analysis included the collection of field duplicate and field blank samples at a rate of 1 in 20, or a minimum of 1 per month.

For a description of the data verification, assay procedures and the quality assurance program and quality control measures applied by Denison, please see Denison's Annual Information Form dated March 26, 2021 filed under the Company's profile on SEDAR at www.sedar.com.

About Phoenix Phase 1

As outlined in the Company's news release dated December 1, 2020, Denison has decided to adapt its plans for the Project to use a phased mining approach, which is expected to allow for the targeted extraction of the least capital-intensive reserves first, based on the grade and distribution of ore in various areas of the deposit. The supporting trade-off study provides for mining to occur over 5 phases.

Phase 1 of the deposit is estimated to contain approximately 22.2 million pounds U3O8 (37,242 tonnes at 27.1% U3O8, above a cut-off grade of 0.8% U3O8) in Probable mineral reserves. Based on current designs, the Company estimates approximately 6.6 million pounds U3O8 (7,717 tonnes at 39.2% U3O8, above a cut-off grade of 0.8% U3O8) in Probable mineral reserves are contained within the expected operating perimeter of the CSWs in the Test Pattern (see Figure 1). These estimates are derived as a direct subset of those reported in the Technical Report titled "Pre-feasibility Study for the Wheeler River Uranium Project, Saskatchewan, Canada" dated October 30, 2018 with an effective date of September 24, 2018. The key assumptions, parameters and methods used to estimate the mineral reserves herein remain unchanged.

About Wheeler River

Wheeler River is the largest undeveloped uranium project in the infrastructure rich eastern portion of the Athabasca Basin region, in northern Saskatchewan – including combined Indicated Mineral Resources of 132.1 million pounds U3O8 (1,809,000 tonnes at an average grade of 3.3% U3O8), plus combined Inferred Mineral Resources of 3.0 million pounds U3O8 (82,000 tonnes at an average grade of 1.7% U3O8). The project is host to the high-grade Phoenix and Gryphon uranium deposits, discovered by Denison in 2008 and 2014, respectively, and is a joint venture between Denison (operator) and JCU (Canada) Exploration Company Limited ("JCU"). Denison has an effective 95% ownership interest in Wheeler River (90% directly, and 5% indirectly through a 50% ownership in JCU).

A PFS was completed for Wheeler River in 2018, considering the potential economic merit of developing the Phoenix deposit as an ISR operation and the Gryphon deposit as a conventional underground mining operation. Taken together, the project is estimated to have mine production of 109.4 million pounds U3O8 over a 14-year mine life, with a base case pre-tax NPV of $1.31 billion (8% discount rate), Internal Rate of Return ("IRR") of 38.7%, and initial pre-production capital expenditures of $322.5 million. The Phoenix ISR operation is estimated to have a stand-alone base case pre-tax NPV of $930.4 million (8% discount rate), IRR of 43.3%, initial pre-production capital expenditures of $322.5 million, and industry leading average operating costs of US$3.33/lb U3O8. The PFS is prepared on a project (100% ownership) and pre-tax basis, as each of the partners to the Wheeler River Joint Venture are subject to different tax and other obligations.

Further details regarding the PFS, including additional scientific and technical information, as well as after-tax results attributable to Denison's ownership interest, are described in greater detail in the NI 43-101 Technical Report titled "Pre-feasibility Study for the Wheeler River Uranium Project, Saskatchewan, Canada" dated October 30, 2018 with an effective date of September 24, 2018. A copy of this report is available on Denison's website and under its profile on SEDAR at www.sedar.com and on EDGAR at www.sec.gov/edgar.shtml.

Denison suspended certain activities at Wheeler River during 2020, including the EA process, which is on the critical path to achieving the project development schedule outlined in the PFS. While the EA process has resumed, the Company is not currently able to estimate the impact to the project development schedule outlined in the PFS, and users are cautioned against relying on the estimates provided therein regarding the start of pre-production activities in 2021 and first production in 2024.

About Denison

Denison is a uranium exploration and development company with interests focused in the Athabasca Basin region of northern Saskatchewan, Canada. In addition to its effective 95% interest in the Wheeler River project, Denison's interests in the Athabasca Basin include a 22.5% ownership interest in the McClean Lake joint venture, which includes several uranium deposits and the McClean Lake uranium mill that is contracted to process the ore from the Cigar Lake mine under a toll milling agreement, plus a 25.17% interest in the Midwest Main and Midwest A deposits, and a 66.90% interest in the Tthe Heldeth Túé ("THT," formerly J Zone) and Huskie deposits on the Waterbury Lake property. The Midwest Main, Midwest A, THT and Huskie deposits are each located within 20 kilometres of the McClean Lake mill.

Through its 50% ownership of JCU, Denison holds additional interests in various uranium project joint ventures in Canada, including the Millennium project (JCU 30.099%), the Kiggavik project (JCU 33.8123%) and Christie Lake (JCU 34.4508%). Denison's exploration portfolio includes further interests in properties covering ~280,000 hectares in the Athabasca Basin region.

Denison is also engaged in mine decommissioning and environmental services through its Closed Mines group (formerly Denison Environmental Services), which manages Denison's Elliot Lake reclamation projects and provides post-closure mine care and maintenance services to a variety of third-party clients.

Follow Denison on Twitter @DenisonMinesCo

Qualified Persons

The disclosure of scientific or technical information related to certain hydrogeological results and interpretations (including the hydrogeological investigations carried out as part of the 2021 ISR Field Test and associated analysis) contained in this release has been reviewed and approved by Mr. David Bronkhorst, P.Eng, Denison's Vice President, Operations and Mr. Andrew Yackulic, P. Geo., Denison's Director, Exploration, who are Qualified Persons in accordance with the requirements of NI 43-101.

Cautionary Statement Regarding Forward-Looking Statements

Certain information contained in this news release constitutes 'forward-looking information', within the meaning of the applicable United States and Canadian legislation, concerning the business, operations and financial performance and condition of Denison.

Generally, these forward-looking statements can be identified by the use of forward-looking terminology such as 'plans', 'expects', 'budget', 'scheduled', 'estimates', 'forecasts', 'intends', 'anticipates', or 'believes', or the negatives and/or variations of such words and phrases, or state that certain actions, events or results 'may', 'could', 'would', 'might' or 'will be taken', 'occur', 'be achieved' or 'has the potential to'.

In particular, this news release contains forward-looking information pertaining to the following: the interpretation of results of the ISR field program, including expectations regarding further de-risking of the ISR mining method; Denison's capitalization to enable further studies; the initiation of the FS and the planned scope, elements, and objectives of the FS; other evaluation activities, objectives and expectations, including the permeameter analysis and the ongoing EA and related processes; the results of the PFS and expectations with respect thereto, including the mineral resource estimates and project designs disclosed to-date and the ability to maintain or build upon such designs; other development and expansion plans and objectives; Denison's COVID-19 and other health and safety protocols; and expectations regarding its joint venture ownership interests and the continuity of its agreements with its partners and third parties.

Forward looking statements are based on the opinions and estimates of management as of the date such statements are made, and they are subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Denison to be materially different from those expressed or implied by such forward-looking statements. For example, the modelling and assumptions upon which the work plans are based may not be maintained after further testing or be representative of actual conditions within the Phoenix deposit. In addition, Denison may decide or otherwise be required to discontinue its field test activities or other testing, evaluation and development work at Wheeler River if it is unable to maintain or otherwise secure the necessary resources (such as testing facilities, capital funding, regulatory approvals, etc.) or operations are otherwise affected by COVID-19 and its potentially far-reaching impacts. Denison believes that the expectations reflected in this forward-looking information are reasonable but no assurance can be given that these expectations will prove to be accurate and results may differ materially from those anticipated in this forward-looking information. For a discussion in respect of risks and other factors that could influence forward-looking events, please refer to the factors discussed in Denison's Annual Information Form dated March 26, 2021 or subsequent quarterly financial reports under the heading 'Risk Factors'. These factors are not, and should not be construed as being exhaustive.

Accordingly, readers should not place undue reliance on forward-looking statements. The forward-looking information contained in this news release is expressly qualified by this cautionary statement. Any forward-looking information and the assumptions made with respect thereto speaks only as of the date of this news release. Denison does not undertake any obligation to publicly update or revise any forward-looking information after the date of this news release to conform such information to actual results or to changes in Denison's expectations except as otherwise required by applicable legislation.

Cautionary Note to United States Investors Concerning Estimates of Mineral Resources and Mineral Reserves: This press release may use terms such as "measured", "indicated" and/or "inferred" mineral resources and "proven" or "probable" mineral reserves, which are terms defined with reference to the guidelines set out in the Canadian Institute of Mining, Metallurgy and Petroleum ("CIM") CIM Definition Standards on Mineral Resources and Mineral Reserves ("CIM Standards"). The Company's descriptions of its projects using CIM Standards may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the United States federal securities laws and the rules and regulations thereunder. . United States investors are cautioned not to assume that all or any part of measured or indicated mineral resources will ever be converted into mineral reserves. United States investors are also cautioned not to assume that all or any part of an inferred mineral resource exists, or is economically or legally mineable.

Figure 1: Plan Map Showing Location of Phoenix Deposit (Phase 1) – ISR Test Pattern

Figure 2: Cross Section Showing Location of Test Pattern Wells at Phase 1

SOURCE Denison Mines Corp.

David Cates, President and Chief Executive Officer, (416) 979-1991 ext 362; Shae Frosst, Investor Relations, (416) 979-1991 ext 228